Press brakes are a major investment and help maintain the rhythm of production schedules and customer orders. To remain competitive in today’s manufacturing world, technology moves faster than ever, with press brakes expected to deliver precision, efficiency, and connectivity. When a press brake starts showing signs of wear and tear, no longer keeping up with production schedules, it may be time to repair or retrofit it.

Determining whether to repair or retrofit a press brake can depend on if your business is producing more complex parts, tighter tolerances, or higher volumes. Repairs are best for short-term fixes or when the machine is still relatively new. Retrofitting is ideal to extend the life of an older, well-built machine while wanting to embrace the efficiencies of modern electrical technology.

Control Works, Inc., with over 30 years of experience, offers responsive support and tailored solutions to repair and revitalize press brakes. The specialists work closely with clients to understand their specific needs, providing easy-to-understand schematics and training.

CONTACT CONTROL WORKS TODAY TO SEE HOW WE CAN ASSIST YOU

Get your press brake back to working condition with minor fixes or easy replacements

Get modern technological upgrades into your existing equipment or rebuild an old press brake into a reliable new machine.

Repair

Repairing a press brake includes fixing or replacing worn-out components, such as hydraulics, mechanical linkages, electrical parts, or the currently used control systems. The goal is to get the press brake back to its original working condition in a short amount of time, without making upgrades.

Control Works offers on-time service assignments and preventative maintenance service programs. Our specialists maximize your organization’s up-time by resolving problems that would have caused a shutdown with extensive repair costs. Control Works utilizes the latest diagnostic equipment available, diagnosing wear and tear problems before they break your press brake.

CONTACT CONTROL WORKS TODAY TO SEE HOW WE CAN ASSIST YOU

On-Site Training

Need training for new employees or have new systems? Control Works has you covered, offering a wide range of customizable courses from basic bending theory to advanced 3D programming. We offer training on most brands and models of press brakes, from basic mechanical machines to multiple-axis CNC press brakes.

Reduce machinery services costs by providing your maintenance technicians the electrical, hydraulic, and control knowledge training they need to complete complex diagnostic and repair tasks. Training can be conducted on-site, off-site, or online. All courses include relevant training materials and comprehensive documentation.

CONTACT CONTROL WORKS TODAY TO SEE HOW WE CAN ASSIST YOU

Retrofit

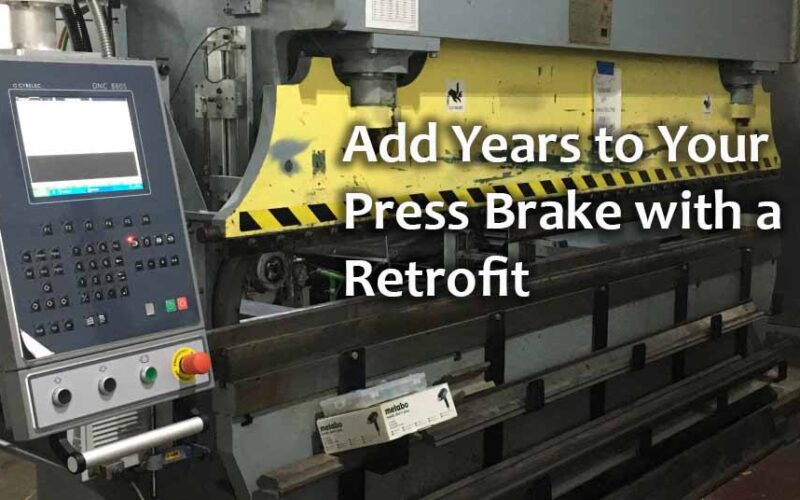

Retrofitting a press brake involves integrating modern technologies into existing equipment, allowing a connection to various systems throughout different interfaces for monitoring, control, and automation. Retrofitting can breathe new life into old equipment, bringing it into the era of Industry 4.0 and help your business with efficiency and productivity.

A proper retrofit can add 10-20 years of functionality to a press brake while improving productivity and consistency. Upgrade electrical systems with some of the latest technological advances, such as modern CNC control systems, backgauge systems, safety features, CAD/CAM software, or even installing newer hydraulic components or servo-driven actuation.

Control Works can turn your old, broken press brake into a productive and reliable machine within less than a week. Our specialists design, build, and install electrical control systems, with many having remote access capabilities for easy diagnosis. Control Works offers partial or complete retrofit options, including:

- New Cybelec control system

- Complete new electrical panel with safety PLC

- New servo drives and motors

- 3.5” touchscreen to display diagnostics information and provide mode switching

CONTACT CONTROL WORKS TODAY TO SEE HOW WE CAN ASSIST YOU