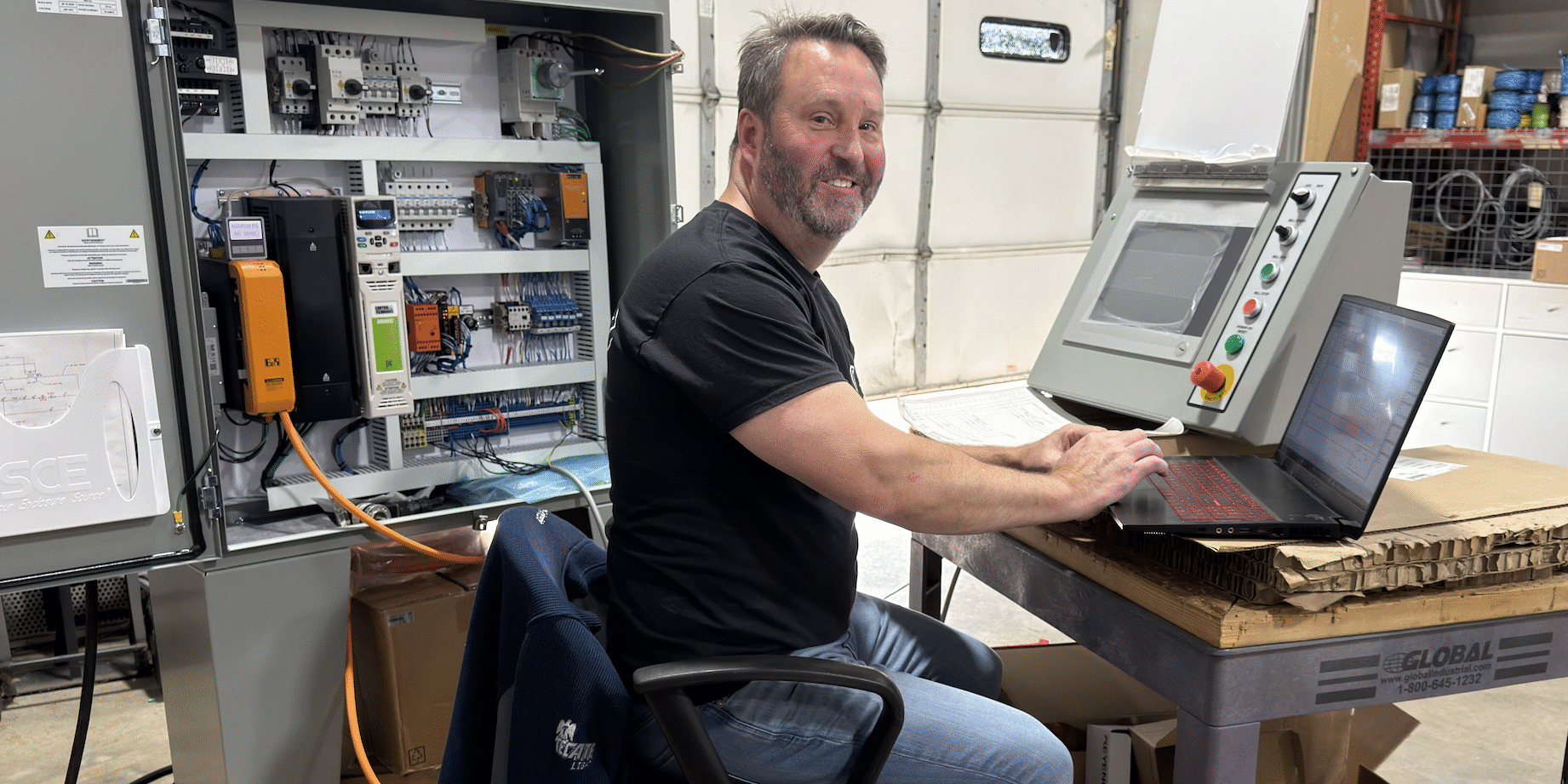

David Locke is one of two owners of Control Works, a control systems and press brake service company.

This blog is an interview with David L., providing some insight into the Control Systems Division of Control Works.

David highlights some of his background, how he helps clients, and his thoughts on the future of control systems.

How did you get into control panel work?

“I was lucky enough that somebody gave me an opportunity in a technical field, installing process monitoring equipment on large industrial presses. I was able to build that into an engineering management position and then on to electrical engineering. One day, I decided that I wanted to convert my knowledge into managing my own business, which is how I got to where I am today.”

Did you start your business out of your garage?

“I did, yes. I started with helping clients with electrical and software design and immediately was drawn into building electrical control panel systems. Clients were asking if I could do anything to update the control panel systems on the old machines they had, so they didn’t have to build entirely new machines. I built the panels in my garage and installed them out in the field. Slowly but surely, I built up a client base of end users and grew the business.”

“The next evolution of just-in-time manufacturing is data-driven. It’s about how much data can be obtained from a machine.”

How did you meet and merge businesses with David Cossey?

“Dave and I met while working different contracts. I was designing and installing control panel systems while he was working on press brakes. We worked together for a while, becoming friends, and I left to start Control Works. He would tell me about a client who wanted an entire control panel rebuild and would ask me to help him out. Over the years, we become closer friends and decided to merge our companies together.”

What makes you stand apart from other companies that build control panel systems?

“I think it’s our attention to detail and trying to keep systems as simple as possible. Simplicity is key, especially to service the equipment later in life. As a reliable partner, we supply proper electrical schematics, support the machinery, and support the software over the long term.

Our first client is still our client to this day, 20 years after starting the business. They’ve grown with us, and we’ve grown with them. We have built more projects for them, and we’ve supported their software. The machines that we’ve controlled for them are all still running and fully supported.

That’s the philosophy we have. We’re not looking at each business as a single one-off application. When we look at a client, we think about what else we can do for them. We bring support now and in the future. We partner with our clients.”

What is the biggest challenge you’ve had in a job?

“In the beginning, the challenge was being a one-man band: Being on-site with clients, installing equipment, communicating with and supporting other clients and potential clients, and continuing the search for the next project. The biggest challenge was keeping the business running as a single business owner.

As far as machinery goes, each machine has unique software requirements. One machine, I had to figure out how to write software to wrap Teflon tape around a copper conductor. Then there was the tube bending machine and writing tube bending and CNC software from scratch. Another machine was working on making medical pouches, feeding Tyvek foam and plastic, heat sealing them together, and cutting them off to a specific length while managing thirty temperature zones.

Every single machine we’ve done has been something new, a challenge which we’ve always lived up to. It’s called no fear.”

You’ve built up a team of builders and programmers at Control Works. Are you more of a one-stop shop?

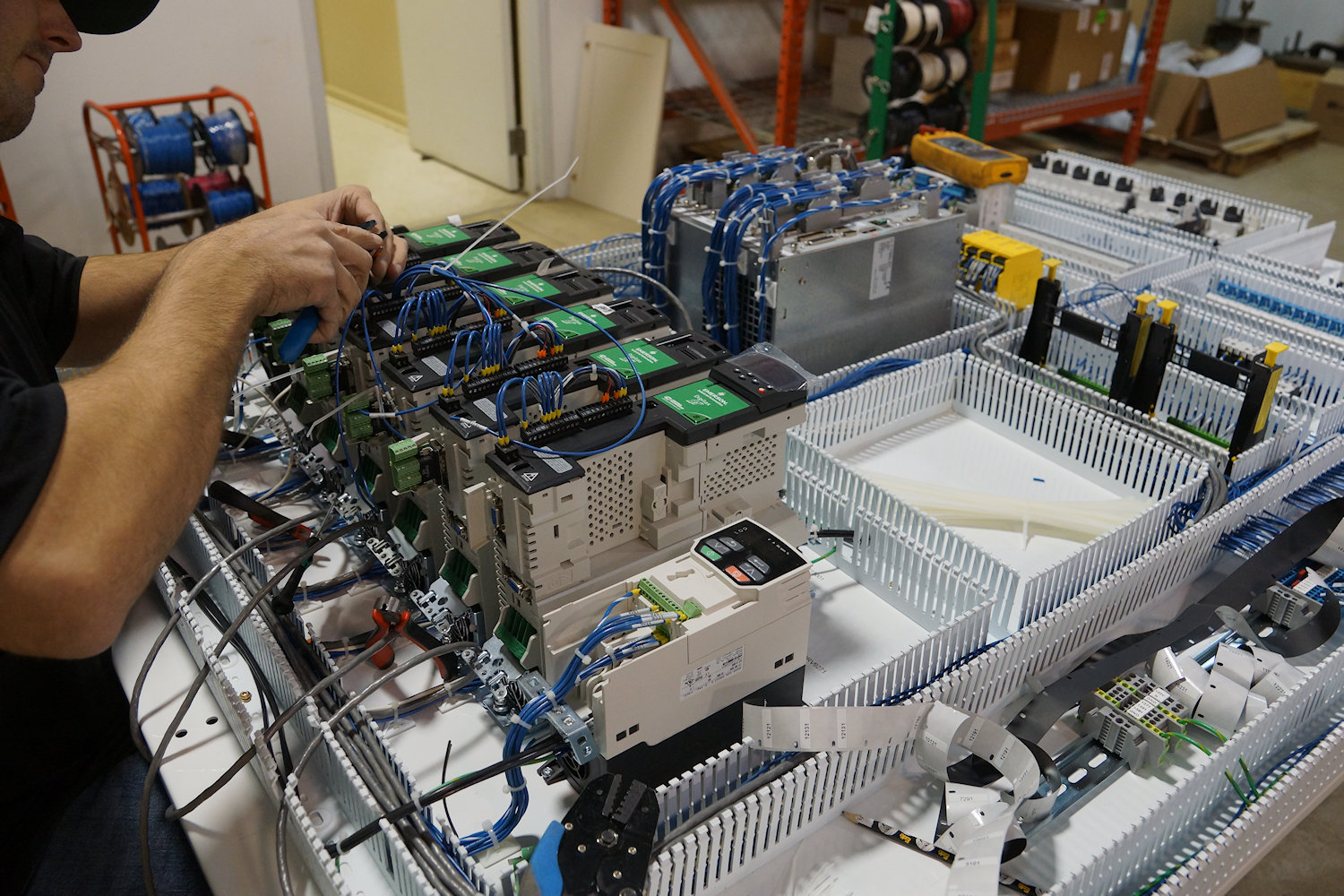

“We like to think we are, and we cater our services. For example, if somebody has a set of schematics and they just want an electrical panel built to those schematics, we can do that. We will take their drawings and designs, we’ll build the electrical panel, test it, and ship it.”

Over the years, you’ve seen a lot of changes. What do you see as the biggest upcoming change in manufacturing panel building?

“The next evolution of just-in-time manufacturing is data-driven. It’s about how much data can be obtained from a machine: what it’s producing, is it producing, when it will finish one production to start the next production, etc. There is a lot of data involved, and we’ve had clients ask us to add modules and sensors from different manufacturers that cannot be merged into a central server so they can collect and interpret data.”

Do you see AI integrating into what you guys are doing in the future?

“It’s coming. We already have applications now that’ll write tidbits of code for you. You just feed the application some general parameters, and it will give you a structure of software that you can plug and play and works out of the box.

The other data-driven aspect is digital twin technology, especially for machine manufacturers and robotics integrators. This is the capability to model in real time on a computer the whole solution.

For example, I have conveyors, and I have a bunch of boxes. Digital twin technology can model how a box is flowing through the conveyors. Then it can model how a robot is going to pick up and place the box. You can determine ahead of time, before you get in a jam, what the robot’s reach is, what the end tooling is going to do — how it’s all going to function.

You can even introduce signals into the process while you’re running it and write code directly on the digital twin that will correlate directly to your machine, which is usable code. You can develop the source code for a machine before the machine is ever made, before a single part of a machine is produced. You can run and test your machine inside of a digital world and write software for that machine.

Digital twin technology and being able to create your machine inside of a simulation is a huge, huge thing that’s coming up. I don’t know if people realize how fast it’s coming, but it is coming.”

How would you describe Control Works to a new customer?

David Locke concludes his interview detailing how Control Works is a resource for your business future.

“We focus on being honest, upfront, communicative, and building a future partnership with our customers.

We tell new and potential customers what we do and how we do it. We discuss the possibility of being a future resource for them, providing long-term relationships and helping businesses move forward with their machinery and control systems.”

From building new control panel systems to retrofitting control panel systems with easy-to-understand schematics and training, the specialists at Control Works have you covered. Contact Control Works today to find out more of what they can do for your control system needs.