Your press brake is a major investment and maintains the rhythm of production schedules and customer orders. And in today’s manufacturing world, technology is moving faster than ever with press brakes expected to deliver precision, efficiency, and connectivity. What happens when your press brake starts showing signs of wear and tear, or can no longer keep up with demands? Should you repair, replace, or retrofit your press brake?

While each option has its own costs, benefits, and long-term implications, choosing whether to repair, replace, or retrofit your press brake can depend upon your production goals, budget, and the condition of your equipment. When making a major decision about your equipment, it helps to understand the differences between the options available to you.

How Many Repairs are Too Many?

Repairing a press brake typically involves fixing or replacing the worn-out components like hydraulics, mechanical linkages, electrical parts, or the currently used control systems. The idea is to get the press brake back to its original working condition without making upgrades. Repairs generally cost less than a replacement or a retrofit and can be completed in a short amount of time, barring any unforeseen complications.

However, repairing may only be putting a patch on an underlying problem that could need to be repaired time and again. And the older the machine is, the harder it can be to find the right replacement parts. Repairing a press brake system also does not include modernizing features, such as adding automation or safety controls, which can grossly impact performance.

Determining whether to repair, replace, or retrofit a press brake is not a one-size-fits-all decision.

Retrofitting a Press Brake

Retrofitting a press brake involves integrating modern technologies into your existing equipment, allowing a connection to various systems throughout different interfaces for monitoring, control, and automation. By retrofitting, you breathe new life into your equipment, bringing it into the era of Industry 4.0 and helping your business with efficiency and productivity.

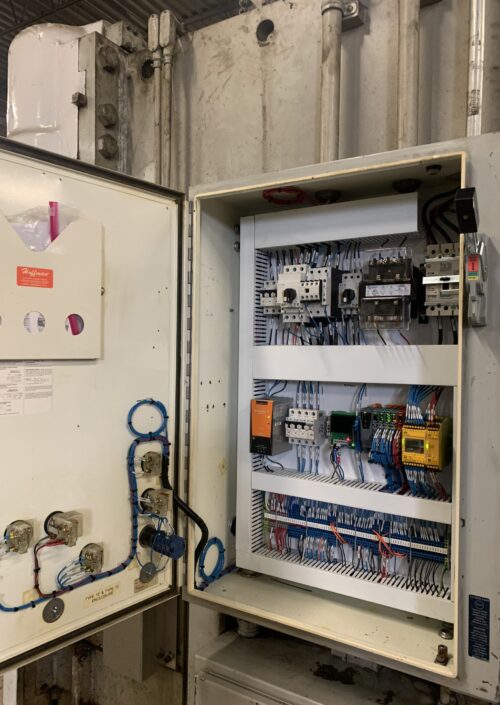

Retrofitting your press brake typically includes upgrading your electrical systems with some of the latest technological advances, such as modern CNC control systems, backguage systems, safety features, CAD/CAM software, or even installing newer hydraulic components or servo-driven actuation. Retrofitting preserves the main frame of the machine while improving its technological capabilities.

Once completed, a press brake can have a completely new control panel and electrical system. A proper retrofit can add 10-20 years of functionality to a press brake while improving productivity and consistency. Retrofitting can be 40-60% less expensive than buying a new press brake and can bring older machines up to today’s safety and productivity standards.

Control Works is the Company to Help You Decide

Determining whether to repair, replace, or retrofit a press brake is not a one-size-fits-all decision. Repairs are best for short-term fixes or when the machine is still relatively new while a complete replacement can be an overly costly and unnecessary expenditure. If you are constantly calling for repair service, you may be throwing a lot of money into a problem that could have already been corrected with a retrofit.

The decision to repair, replace, or retrofit can also depend on if your business is producing more complex parts, tighter tolerances, or higher volumes than was previously done. Retrofitting a press brake is ideal for companies looking to extend the life of an older, well-built machine while wanting to embrace the efficiencies of modern electrical technology.

Overall, if the electrical components of your press brake are outdated, retrofitting your machine can increase productivity, provide better quality and uniformity, improve safety, and extend the life of your machine for a better ROI. Partnering with a reputable UL508A certified company that understands the complexities of whether to repair or retrofit the electrical components of your press brake machine can help truly assess your machine’s condition and recommend the most cost-effective path forward.

Since starting their company in 2005, Control Works, Inc. has been helping customers to clean up the clutter and revitalize their control panel systems and press brakes. The specialists at Control Works, a UL508A certified company, work closely with clients to understand their specific needs, offering responsive support and tailored solutions that larger companies often can’t match. From a simple press brake repair to a full retrofit with easy-to-understand schematics and training, the specialists at Control Works have you covered.

Contact Control Works today to find out more of what they can do for your control panel needs.