Metal fabrication is critical to your business, and in today’s fast-paced world, it is essential to keep your machine in top working order. The precision of your machine relies heavily on the CNC control system (also called smart motion control), which governs the machine’s speed, position, and synchronization. When the control begins to fail, your business faces the decision to repair or replace it. How do you decide which is better for your business?

Both options can restore functionality, but the right choice can depend on the age of your system, the extent of the damage, the availability of parts, and your long-term production goals.

Understanding CNC Control in Press Brakes

Most press brakes use smart motion control systems to coordinate hydraulic, mechanical, or servo-driven components. These systems integrate sensors, drives, PLCs, and HMIs to ensure precise bending angles, repeatability, and safe operation.

A well-functioning motion control system enhances:

- Bend accuracy and consistency

- Cycle efficiency and speed

- Energy use optimization

- Operator safety and diagnostic visibility

If the system malfunctions, it can cripple a business, causing downtime, misaligned parts, and stifling productivity.

Deciding whether to repair or replace a CNC control system will depend on many factors, including your press brake’s age, performance needs, production demands, and cost.

When a Repair Makes Sense

Repairing a CNC control system can be a smart option in certain cases, especially when the core technology is still current. Choosing to repair a smart motion control makes greater sense when:

- The system is less than 10 years old. Modern drives and controllers have long lifespans, and many issues (like sensor faults or minor electronic failures) can be resolved without full replacement.

- Replacement parts are still available. If a manufacturer still supports the hardware, repairs can often be done quickly and affordably.

- The issue is isolated. Problems such as a single drive failure, faulty encoder, or damaged wiring can often be fixed without impacting the rest of the system.

- Budget or production schedules demand minimal downtime. Repairs are generally faster and less expensive than full replacements, allowing you to resume production quickly.

When a Replacement is the Better Option

If your system is outdated or experiencing repeated issues, replacement can provide a better long-term return on investment. Replacing the CNC control makes more sense when:

- The system is obsolete. Older motion control components (especially those no longer supported by the OEM) pose risks for downtime and part availability.

- You want to upgrade performance and connectivity. Newer smart motion systems integrate advanced features like adaptive bending algorithms, remote monitoring, and data-driven performance analysis, which are critical for modern, Industry 4.0-enabled operations.

- The cost of repair approaches replacement. If repairing an older system costs almost as much as a new system, replacement becomes the more cost-effective and reliable choice.

- You’re already planning a retrofit. Replacing the motion control during a press brake retrofit can modernize your entire machine, upgrading not just control precision but also safety, efficiency, and integration capabilities.

The Middle Ground: Retrofitting

Retrofitting your systems can be the best of both worlds. By upgrading the CNC control system while retaining the existing press brake frame and hydraulics, you can achieve near-new performance at a fraction of the cost of a full machine replacement.

Modern retrofits often include:

- New PLCs and motion controllers

- Updated servo drives and feedback systems

- Touchscreen HMIs with advanced diagnostics

- Enhanced safety interlocks and light curtains

This approach extends machine life, boosts productivity, and ensures long-term parts availability.

Control Works Brings a Smarter Standard

Deciding whether to repair or replace a CNC control system will depend on many factors, including your press brake’s age, performance needs, production demands, and cost. Repairs are best suited for newer, easily serviceable systems with isolated problems. Replacements or retrofitting are better for outdated or unreliable systems that could benefit from modern technological advancements.

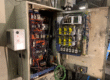

Control Works, Inc. specializes in UL508A-Certified code-compliant, performance driven, control panel systems that maximize uptime and minimize risk. The specialists at Control Works work closely with clients to understand their specific needs, offering responsive support and tailored solutions that larger companies often can’t match.

Partnering with an experienced control system integrator that is UL508A-certified ensures that whichever path you choose, your press brake remains reliable, compliant, and optimized for performance. At Control Works, it’s about the relationship, not the sale.

Contact Control Works today to find out more about what they can do for your smart motion control needs.